Have you found

what you're looking for?

Contact our team of experts

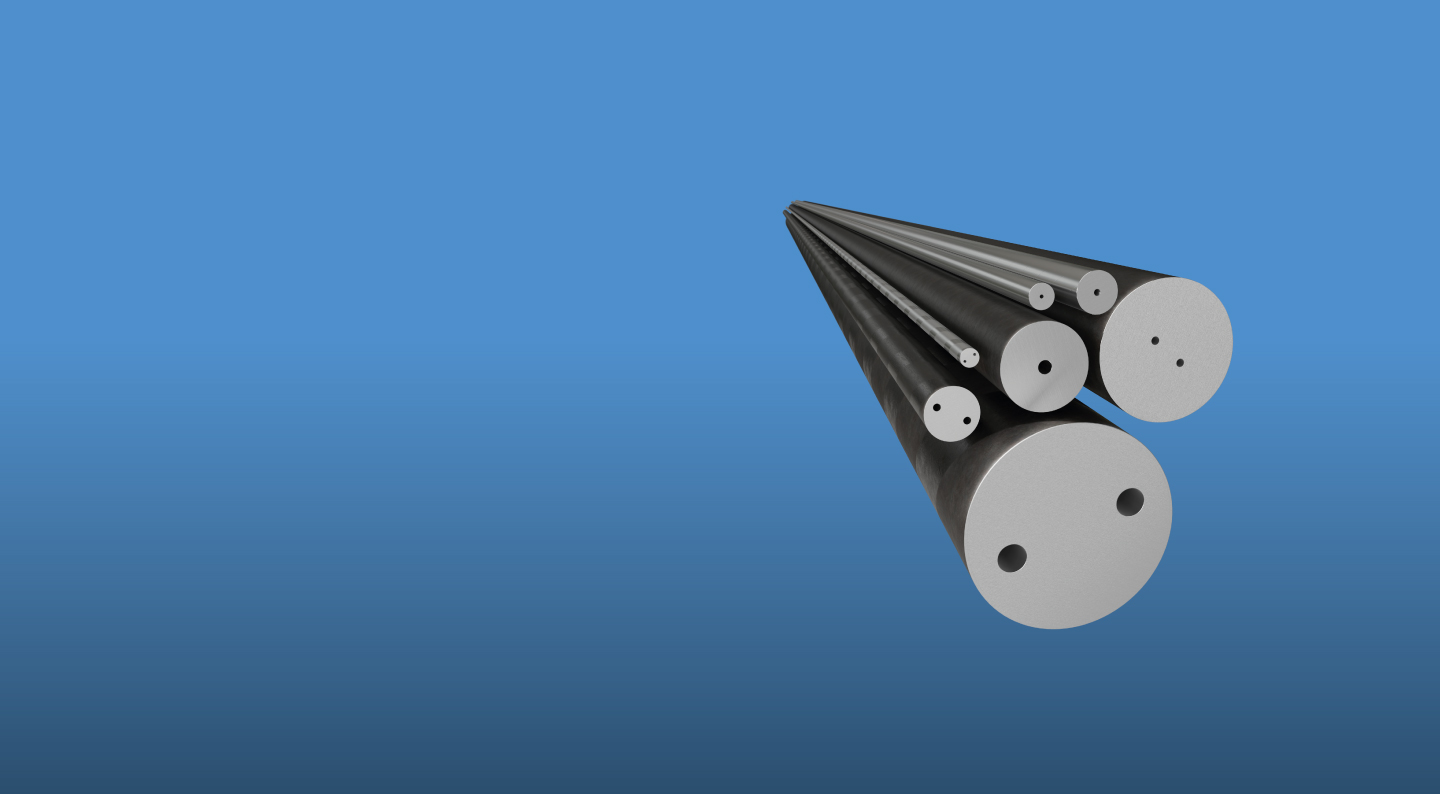

Precision and efficiency are key in the world of manufacturing and production. At the heart of these elements are cutting tools, such as drills, taps and tool bodies. These tools play a vital role in a wide range of industries, from construction to precision machining. Our hole bars (in high-speed steel (HSS) or tool steel) are more than just components; they are the key to cutting tool performance.

The advantages of holes for cutting tools

Our hole bar solutions are designed with efficiency, durability and precision in mind. The presence of holes improves heat dissipation, thus prolonging tool life by minimizing the effects of excessive heat. The holes enhance lubrication and cooling during machining, which is essential for efficient, high-quality cutting operations.

Forécreu hole bars

Our proven technology is based on an industrial process that is unique in the world, guaranteeing the quality and reliability of our products. Our bars are delivered ready for machining, eliminating the time-consuming step of drilling. You can thus optimize your production costs per part, focusing on your core business and improving the efficiency of your production process.

Furthermore, our hole bars reduce your production times and streamline your workflows. This gives you greater control over your risks and boosts your organization’s performance. This increased efficiency gives you the agility you need to respond to ever-changing market demands. By choosing Forécreu hole bars, you are investing in quality, durability and performance, while optimizing your costs and achieving efficiency gains.

Video

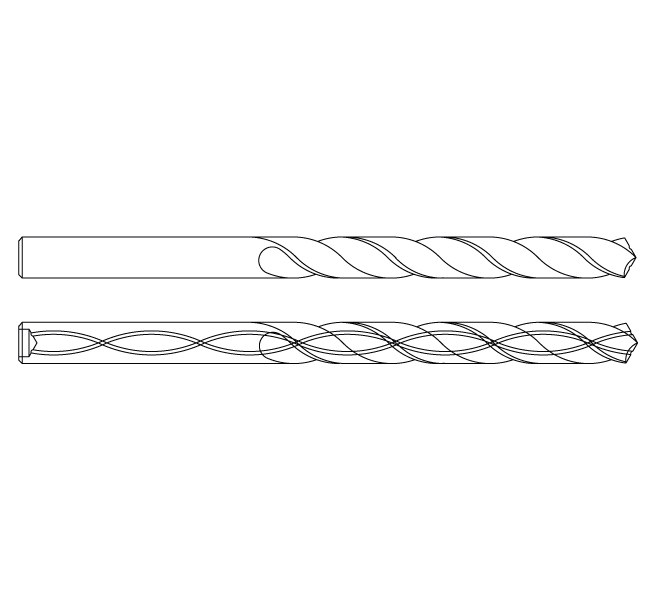

We pioneered the use of hole bar technology to produce drills. Our expertise is based on proven technology that is unique in the world. Our 2-hole straight or twisted bars are delivered ready to machine, eliminating the drilling stage, thus optimizing production costs per part and simplifying the drill manufacturing process.

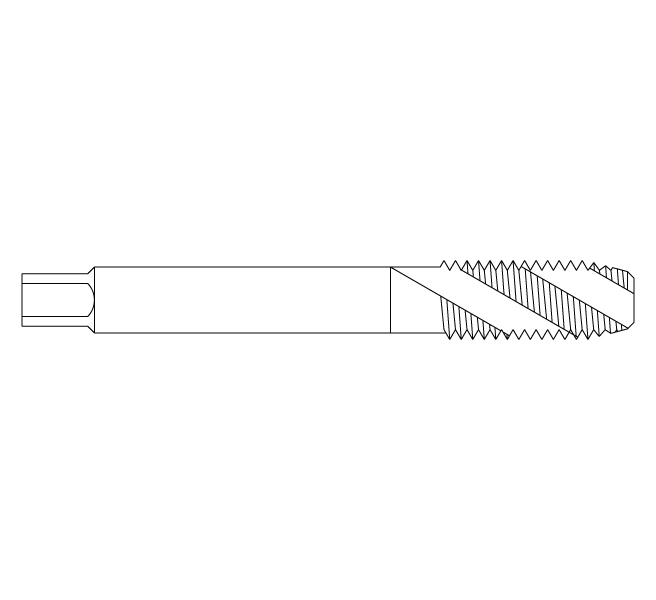

Taps are precision tools used for threading parts, and their success depends on equally precise components. Center-hole bars, specially designed for taps, are crucial to the production of these tools. Our unique industrial process ensures tight tolerances, essential for precise threading of parts.

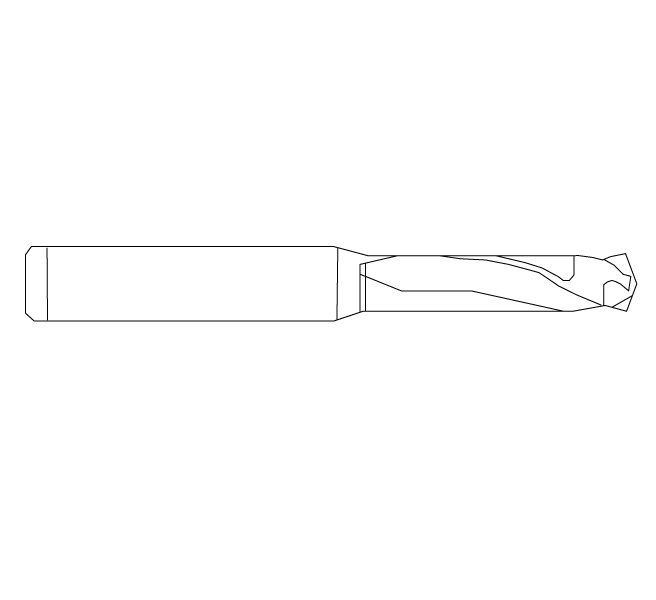

Our hole bars are used for modular drills: combined with carbide inserts, they cover a wide range of applications. These drills deliver improved performance through cost reduction and optimized tool management. We supply straight or twisted bars to suit your projects.

With over 70 years’ experience, we have perfected our production methods and organization to meet your needs and expectations.

Contact our team of experts