The benefits of high-speed steels for tap manufacturing

High-Speed Steel (HSS) is the material of choice for the manufacture of taps. Here’s why HSS taps are widely preferred in the industry

In the world of industry and machining, precision and efficiency are essential to ensure the quality of finished products. This is where taps, used to create threads, play a crucial role. At Forécreu, we’re committed to providing you with customized solutions for tap manufacturing, using center-hole bars made from high-speed steels (HSS). Find out how our products meet the industry’s needs in terms of size, performance and durability.

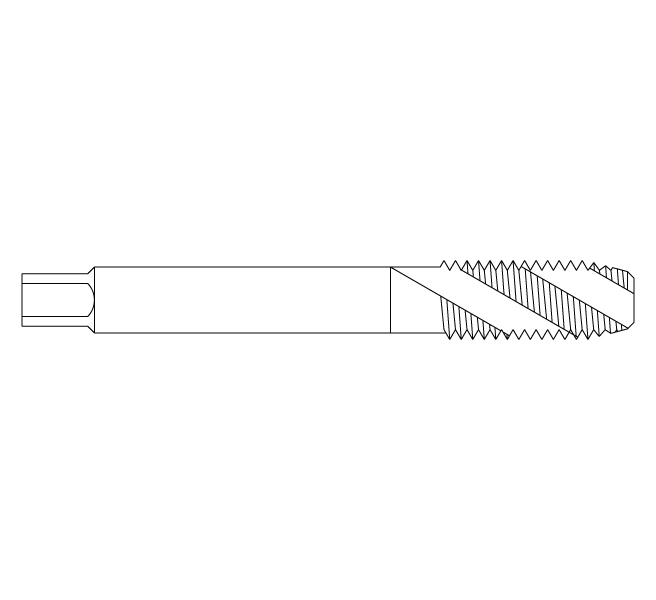

Taps are essential tools in industry, used to create internal threads in metal parts, plastics and other materials. They are essential for assembling components, for fastening and for creating complex parts. The quality of the thread created depends largely on the precision and durability of the tap used.

High-Speed Steel (HSS) is the material of choice for the manufacture of taps. Here’s why HSS taps are widely preferred in the industry

HSS taps are tempered to achieve outstanding hardness. This means they can withstand high loads, drill efficiently and retain their sharpness over time. The hardness of HSS taps guarantees increased durability.

During the tapping process, heat is generated by friction. HSS taps are designed to withstand these high temperatures, ensuring that the tool remains efficient and does not warp during use.

HSS taps are capable of withstanding wear and abrasion, enabling strict dimensional tolerances and consistent thread quality to be maintained.

HSS taps are ideal for high-speed applications, enabling faster and more efficient work.

The center hole in a tap is more than just a feature; it’s a key element in optimizing the tool’s performance. Here’s why it is so important:

Precise guidance

The center hole guides the tap precisely into the material, ensuring controlled penetration and precise threading. This reduces the risk of deviation or misalignment.

Chip evacuation

Chips are generated during the tapping process. The center hole ensures efficient chip evacuation, preventing tool clogging and guaranteeing clean threads.

Reduced torque

The center hole reduces the torque required for tapping, making it easier and less tiring for the operator.

Meeting industry standards in terms of dimensions

At Forécreu, we understand the importance of precision and compliance with industry standards. Our center-hole bar solutions for tap manufacturing meet industry standards for dimensional accuracy.

| Grade PM30 | ||||

| Outside Ø (mm) | Internal Ø (mm) | kg/m | Code | |

| Ground bar ISO h9 | 6.40 | 0.90 | 0.247 | GTS |

| Ground bar ISO h9 | 6.40 | 1.05 | 0.255 | GT |

| Ground bar ISO h9 | 8.40 | 1.35 | 0.441 | GT |

| Ground bar ISO h9 | 10.40 | 1.65 | 0.676 | GT |

| Ground bar ISO h9 | 12.40 | 2.00 | 0.960 | GT |

| Ground bar ISO h9 | 14.40 | 2.30 | 1.250 | GT |

| Ground bar ISO h9 | 16.40 | 2.60 | 1.680 | GT |

| Black bar | 20.00 | 3.10 | 2.50 | GT |

| Black bar | 22.00 | 3.40 | 3.03 | GT |

| Grade PM15 | ||||

| Outside Ø (mm) | Internal Ø (mm) | kg/m | Code | |

| Ground bar ISO h9 | 6.40 | 1.05 | 0.255 | GT |

| Ground bar ISO h9 | 8.40 | 1.35 | 0.441 | GT |

| Ground bar ISO h9 | 10.40 | 1.65 | 0.676 | GT |

| Ground bar ISO h9 | 12.40 | 2.00 | 0.0960 | GT |

| Ground bar ISO h9 | 14.40 | 2.30 | 1.250 | GT |

| Ground bar ISO h9 | 16.40 | 2.60 | 1.680 | GT |

| Grade PM52 | ||||

| Outside Ø (mm) | Internal Ø (mm) | kg/m | Code | |

| Ground bar ISO h9 | 6.40 | 1.05 | 0.255 | GT |

| Ground bar ISO h9 | 8.40 | 1.35 | 0.441 | GT |

| Ground bar ISO h9 | 10.40 | 1.65 | 0.676 | GT |

| Ground bar ISO h9 | 12.40 | 2.00 | 0.0960 | GT |

| Grade M35 | ||||

| Outside Ø (mm) | Internal Ø (mm) | kg/m | Code | |

| Ground bar ISO h9 | 6.40 | 0.90 | 0.247 | GTS |

| Ground bar ISO h9 | 6.40 | 1.05 | 0.255 | GT |

| Ground bar ISO h9 | 8.40 | 1.35 | 0.441 | GT |

| Ground bar ISO h9 | 10.40 | 1.65 | 0.676 | GT |

| Ground bar ISO h9 | 12.40 | 2.00 | 0.960 | GT |

| Ground bar ISO h9 | 14.40 | 2.30 | 1.250 | GT |

| Ground bar ISO h9 | 16.40 | 2.60 | 1.680 | GT |

| Black bar | 20.00 | 3.10 | 2.50 | GT |

| Black bar | 22.00 | 3.40 | 3.03 | GT |

An innovative tool designed to support you in the realization of your projects.

We look forward to answering your questions and assisting you as soon as possible.

Our stock pages are available 24/7 and can be accessed from anywhere in the world.

An innovative tool designed to support you in the realization of your projects.

With over 70 years of experience, we have perfected our production methods and organization to meet your needs and expectations.

Contact our team of experts