Have you found

what you're looking for?

Contact our team of experts

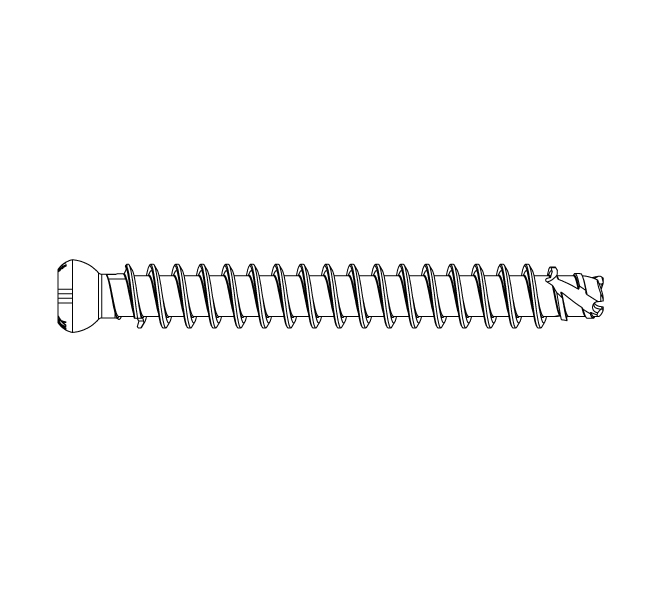

In the ever-changing world of Orthopedics, technological advances have paved the way for increasingly innovative solutions for the well-being of our patients. These advances include medical implants made from cannulated bars, which have contributed to the development of orthopedic surgery and sports medicine, by bringing precision and safety. Screws and nails made from our cannulated bars are mainly used to repair bone or joint fractures. These implants fix the various fracture fragments in position (osteosynthesis technique), while the fracture heals. The orthopedic sectors we serve are traumatology, extremities, spinal and sports medicine.

The mechanical and biological properties of the metals used in bone trauma have been known for many years.

They combine mechanical properties, corrosion resistance and biocompatibility. The high corrosion resistance of steel is mainly due to the protective layer of chromium oxide on the metal surface. All stainless steels used in bone traumatology are non-magnetic. The most commonly used grades are 316 implant-grade (1.4441) and nitrogen-doped grade (1.4472). These materials are highly ductile and can withstand high loads.

These are the most biocompatible of known metals, owing to their incomparable advantages: lightweight, non-toxic, non-magnetic, excellent wear resistance, very good fatigue and corrosion resistance. The most widely used titanium alloy is TiAl6V4, which accounts for over 80% of the global biomedical titanium alloy market. Another alloy used is TiAl6Nb7. Implants made from these alloys are well equipped to withstand high stresses.

The demands placed on medical implants are high, as these devices need to withstand significant loads and stresses. Implantable stainless steels and implantable titanium alloys offer a unique combination of strength and lightness. This durability ensures that implants are efficient and reliable.

Forécreu is ISO 13485 certified. This international standard specifies the requirements for the quality management systems (QMS) used in the medical device industry. The main aspects of the standard that are relevant to us are: compliance with regulatory requirements, control of special processes and traceability of each product delivered.

We offer a wide range of standard ground finished items for sale, or items manufactured to our customers’ specifications. Cannulated bars offer many advantages to medical device manufacturers, including reduced logistics, faster bar implementation and increased production capacity.

| Characteristic | Stainless Steels | Titanium Alloys | |||

| OD | Black finished | Outside diameter | 4 < Ø < 14 mm | +0.30/-0.10 mm | +0.30/-0.10 mm |

| 14 < Ø < 18 mm | +0.50/-0.15 mm | +0.50/-0.15 mm | |||

| 18 < Ø < 21 mm | +0.60/-0.20 mm | – | |||

| Ground finished | Outside diameter (OD) | ISO h9 | |||

| Roughness | Ra 1.6μm | ||||

| ID | Inside diameter | ID ≤ 1 mm : +/-0.05 mm ID > 1 mm : +/- 5% ID |

|||

| e | Eccentricity | ≤ 1.6%OD | |||

| Ground bars (Straightness) | <1 mm/m | ||||

We look forward to answering your questions and assisting you as soon as possible.

Our stock pages are available 24/7 and can be accessed from anywhere in the world.

An innovative tool designed to support you in the realization of your projects.

With over 70 years of experience, we have perfected our production methods and organization to meet your needs and expectations.

Contact our team of experts