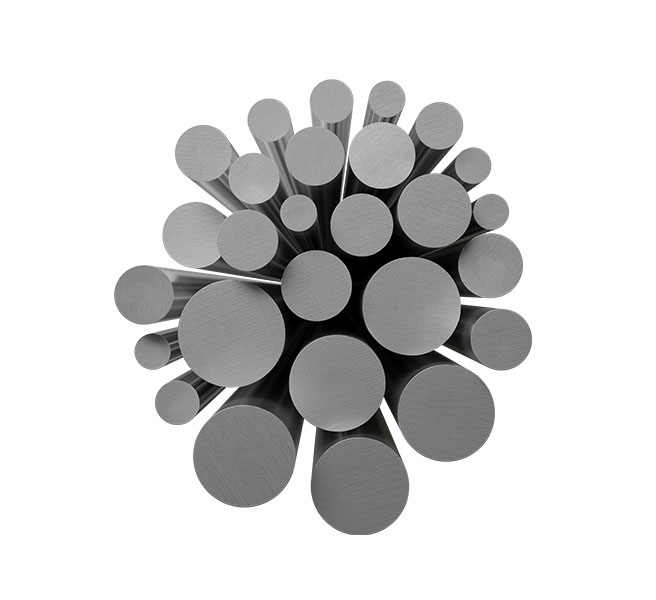

Pre-treated solid bars: time saving and guaranteed quality

One of the distinguishing features of our solid bars is the pre-treatment they undergo. This pre-treatment process is designed to offer our customers a dual advantage.

Welcome to our page dedicated to solid bars and their essential role in medical instrumentation. We are proud to promote the quality of the stainless steels we use to manufacture our solid bars. What’s more, we showcase the time-saving offered by our pre-treated solid bars, thanks to an optimized manufacturing process while guaranteeing quality features such as hardness/corrosion ratio and uniform tool straightness at every point.

When it comes to medical instrumentation, the quality of the materials used is paramount. At Forécreu, we have chosen to use high-quality stainless steel for our solid bars. This stainless steel is corrosion-resistant, durable and has an excellent ability to maintain reliable mechanical properties in demanding environments.

One of the distinguishing features of our solid bars is the pre-treatment they undergo. This pre-treatment process is designed to offer our customers a dual advantage.

Our pre-treated solid bars are delivered ready for machining, eliminating the need for multiple preparation steps. This saves you valuable time in the manufacturing phase of your medical instruments.

Pre-treatment ensures an optimum hardness/corrosion ratio, guaranteeing corrosion resistance while maintaining appropriate hardness levels. What’s more, the tool’s uniform straightness (1 mm per 1000 mm) is maintained at every point on the bar, which is essential for the precision of your instruments.

Solid pre-treated bar solutions in stainless steel with a diameter 2–12 mm, for the production of

your medical tools and instruments.

Pre-treated bars save time thanks to a shortened manufacturing process which maintains the

tool’s hardness/corrosion ratio and uniform straightness throughout.

| Solid bars | 420B | ||||

| Black outside Ø | Rectification ISO |

Length | Hardness HV20 |

Straightness |

| 2.0 mm | h8 | 2000 mm | 550 – 590 | 1 mm/ 1000 mm |

| 2.5 mm | ||||

| 3.0 mm | ||||

| 3.5 mm | ||||

| 4.5 mm | ||||

| 5.0 mm | ||||

| 6.0 mm | ||||

| 8.0 mm | ||||

| 10.0 mm | ||||

| 12.0 mm | ||||

We look forward to answering your questions and assisting you as soon as possible.

Our stock pages are available 24/7 and can be accessed from anywhere in the world.

An innovative tool designed to support you in the realization of your projects.

With over 70 years’ experience, we have perfected our production methods and organization to meet your needs and expectations.7

Contact our team of experts